Welcome to the official website of Yantai Changyun Electronics Co., Ltd.Tel:0535-6930766

DATE:【2021-10-09 11:51】 TIPS:【】次

WriteNow! programmer supports the automotive PSI5 Peripheral Sensor Interface

Recently Algocraft has developed an automotive application based on Bosch SMA731 IC. SMA731 is a low-g acceleration sensor conform to PSI5 specification revision 1.3 and 2.1.

The Peripheral Sensor Interface (PSI5) is an interface for automotive sensor applications. The PSI5 organization is composed by a “Steering Committee" formed by Veoneer, Bosch and Continental and “Members” which includes the most important chip producers and companies operating in the automotive field (https://www.psi5.org)

PSI5 is designed to meet the requirements of a universal and highly reliable automotive sensor interface at the lowest possible implementation costs. PSI 5 was originally developed to be used in airbag applications. However, the mid-range data transmission rate of 125 kbps, covers most of the automotive sensor applications and offers enough bandwidth for a lot of multi-channel sensor configurations.

PSI5 protocol has the following characteristics:

Two-wire current interface;

Bidirectional communication;

Manchester coded digital data transmission;

High data transmission speed of 125 kbps or 189 kbps;

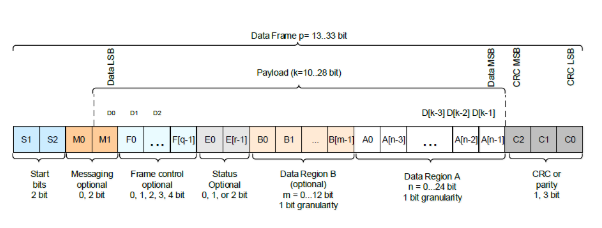

Variable frames and data word length;

Different bus modes.

The communication from the programmer to the sensor is realized by voltage modulation on the supply line according to Tooth Gap method (‘1’ is a sync pulse during the appropriate time interval, ‘0’ is the absence of sync pulse) or Pulse Width method (‘1’ is a long sync pulse, ‘0’ is a short sync pulse):

The communication from the sensor to the programmer, instead, is done by current modulation of the power supply:

a “low-level” is the normal consumption of the sensor and an “high-level” is realized by an increased current sink of the sensor.

For the programming of the OTP registers of Bosch SMA731 the communication from the programmer to the sensor follows the Tooth Gap method for the voltage modulation.

The first command to enable the device service mode must be sent with 500 us sync pulse period; all the other commands require 120 us sync pulse period.

The standard for sensor to ECU communication is PSI5 P10P-500/4H (10 data bits, 1 parity bit, 500 us cycle time and 189 kbps bitrate).

For implementing the lower layers of PSI5 interface, Algocraft designed and realized an appropriate adapter compatible with the ISP connector of WriteNow! programmer.

The adapter is realized with discrete components and provides the PSI5 analog/digital front-end.

The adapter is composed by 3 circuits: power supply, injector and receiver.

The injector manages the voltage supply modulation on target supply line during the communication from the programmer to the sensor.

The receiver executes the sensing of the current on target supply line and decodes the current modulation during the communication from the sensor.

Three signals are used for the communication:

WriteNow! PSI5 Adapter provides a 48 ways female DIN41612 for connection to WriteNow! ISP connector and a 48 ways male DIN41612 for connection up to 4 targets.

It must be supplied directly from WriteNow! programmer.

It doesn’t require any external supply.

WriteNow! solution allows to program in parallel up to 8 sensors via PSI5 interface using 2 WriteNow! PSI5 adapter.

Algocraft confirms itself as a leader in the programming of sensors and ICs.